Improve productivity and efficiency in underwater construction applications. Trimble Marine Construction systems provide accurate 3D visualisation to assist the operator with underwater construction tasks.

Trimble Marine Construction Systems

Machine Guidance for Wire Crane Block Placement

How It Works

Features and Benefits

Trimble Marine Construction systems are flexible, high-performance positioning systems that meet the unique needs of marine construction on both simple and complex projects.

-

Accurate Placement

Accurate Placement

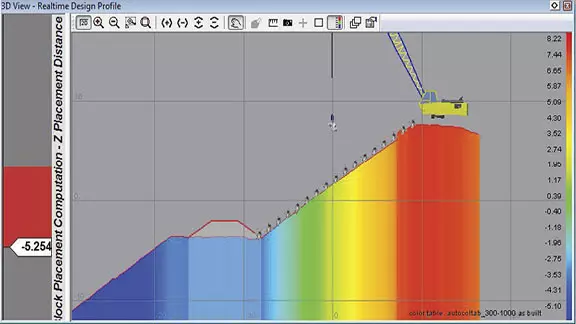

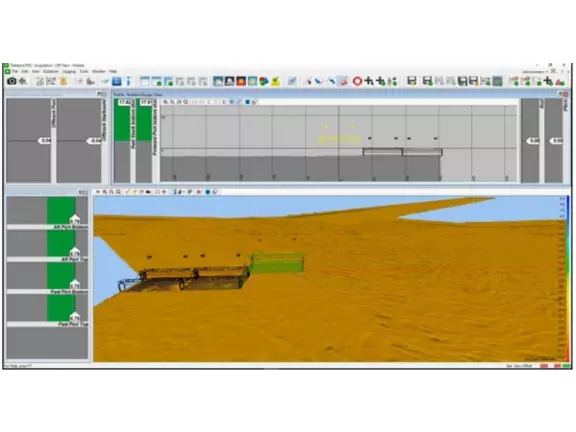

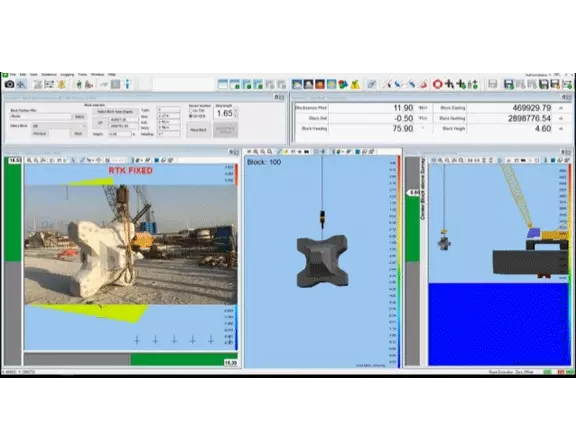

The operator has a real-time view of the excavator, crane and barge in plan and profile views. Profile displays show tool depth along with the surveyed and design depths.

- Tolerance visualisation provides guidance for accurate, efficient dredging and placement productivity

- RTK can be used for precise tide and heave measurement

- Third party laser for non-vertical wire

- Third party detachable sensor for block orientation during placement

-

Real-Time Visualisation and Monitoring

Real-Time Visualisation and Monitoring

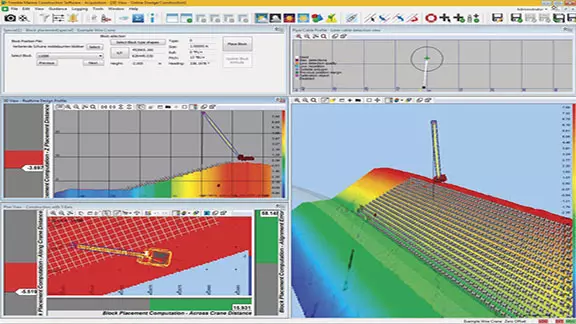

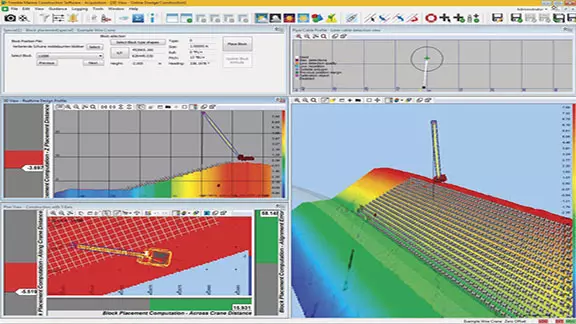

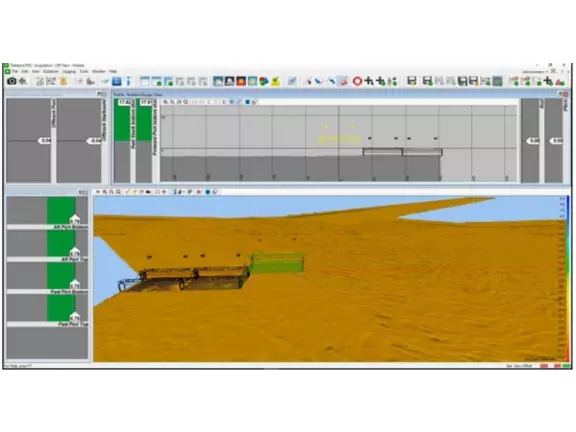

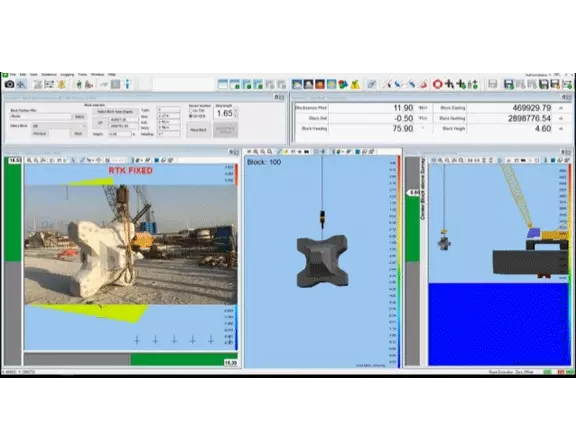

Real-time views of the machine in plan, profile and 3D displays the object being placed and its associated design location and orientation with both visual and numeric guidance for the operator. This ‘Eyes below the water’ approach provides the tools necessary for precise underwater placement and seawall construction operations.

- Supports real time sonar inputs providing as-building capability

- Continuous data logging for as-building and volume reports

-

Real-Time Seafloor and Design

Real-Time Seafloor and Design

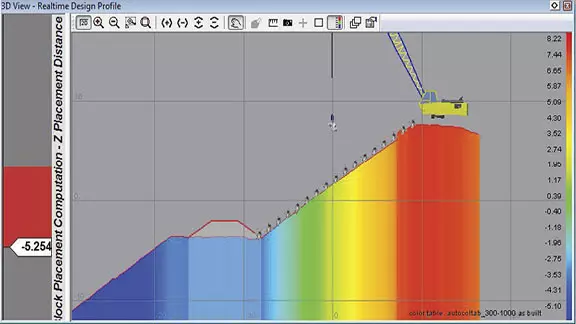

Up/down indicators show the operator the exact distance to the design surface continuously. The software supports complex 3D designs.

-

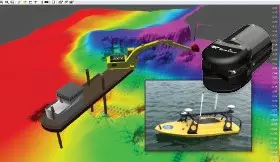

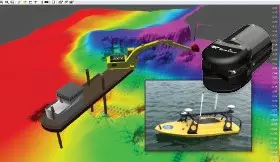

Sonar imaging for underwater visualisation

Sonar imaging for underwater visualisation

Add eyes below the water with Teledyne Marine sonars for real-time data visualisation.

-

Intuitive and Flexible Workflows

Intuitive and Flexible Workflows

The software makes it easy to select block designs and monitor the block placement process. Block position is calculated by the crane’s position and measuring the angle and pay-out of the hoisting wires. If the wire is not vertical due to tide or current, a laser can be added for improved positioning.

- Barge or land-based workflows

- Import or build project design and survey models in the office or field for operations

- Robust and reliable solutions maximise uptime

-

Customisable Interface

Customisable Interface

Multiple monitors with independent layouts can be tailored to the needs of the operator. A color-coded plan view and 3D view highlights surface high and low spots. The surface Digital Terrain Model (DTM) is updated in real-time registering construction progress showing depth, differential and production models.

- Administrator can configure the screens for a specific workflow/user and lock it down for the operator

-

Accurate Placement

Accurate Placement

The operator has a real-time view of the excavator, crane and barge in plan and profile views. Profile displays show tool depth along with the surveyed and design depths.

- Tolerance visualisation provides guidance for accurate, efficient dredging and placement productivity

- RTK can be used for precise tide and heave measurement

- Third party laser for non-vertical wire

- Third party detachable sensor for block orientation during placement

-

Real-Time Visualisation and Monitoring

Real-Time Visualisation and Monitoring

Real-time views of the machine in plan, profile and 3D displays the object being placed and its associated design location and orientation with both visual and numeric guidance for the operator. This ‘Eyes below the water’ approach provides the tools necessary for precise underwater placement and seawall construction operations.

- Supports real time sonar inputs providing as-building capability

- Continuous data logging for as-building and volume reports

-

Real-Time Seafloor and Design

Real-Time Seafloor and Design

Up/down indicators show the operator the exact distance to the design surface continuously. The software supports complex 3D designs.

-

Sonar imaging for underwater visualisation

Sonar imaging for underwater visualisation

Add eyes below the water with Teledyne Marine sonars for real-time data visualisation.

-

Intuitive and Flexible Workflows

Intuitive and Flexible Workflows

The software makes it easy to select block designs and monitor the block placement process. Block position is calculated by the crane’s position and measuring the angle and pay-out of the hoisting wires. If the wire is not vertical due to tide or current, a laser can be added for improved positioning.

- Barge or land-based workflows

- Import or build project design and survey models in the office or field for operations

- Robust and reliable solutions maximise uptime

-

Customisable Interface

Customisable Interface

Multiple monitors with independent layouts can be tailored to the needs of the operator. A color-coded plan view and 3D view highlights surface high and low spots. The surface Digital Terrain Model (DTM) is updated in real-time registering construction progress showing depth, differential and production models.

- Administrator can configure the screens for a specific workflow/user and lock it down for the operator

Applications

- Rock dumping and placement

- Caisson placement

- Block placement using wire crane or excavator

- Vertical and raked pile placement